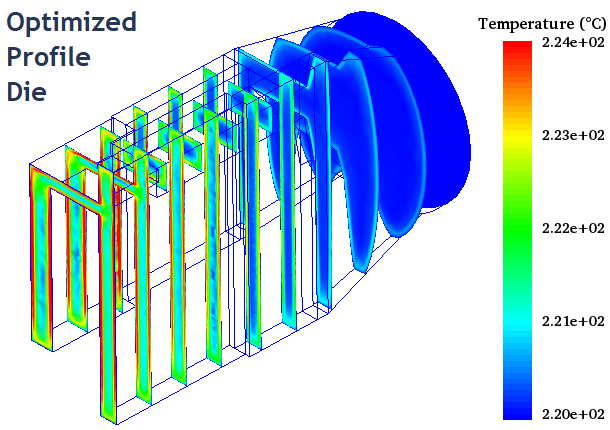

The optiXtrue software has been successfully used to automatically optimize extrusion dies without any user interaction. Some of the dies optimized by optiXtrue are shown below.

The optiXtrue software optimizes extrusion die geometry such that the extrudate distortion after the polymer leaves the die is minimized. Instead of user fine-tuning the die geometry after each flow simulation, the optiXtrue software automatically fine-tunes the die geometry for you and restarts the flow simulation in the fine tuned die. This automatic iterative fine-tuning of the die is continued till an optimized die with the minimum velocity variation at the die exit is obtained. A uniform exit velocity distribution with minimum variation is critical for minimizing the extrudate distortion. OptiXtrue also allows the user to specify a pressure limit for the die, such that the pressure drop in the optimized die is below the specified pressure limit.

In order to optimize an extrusion die, optiXtrue requires that critical dimensions of the die, which have the maximum effect on the exit velocity distribution, are parameterized. That is, are designated as variables in SolidWorks or Inventor software. For each parameterized dimension, the user also specifies the range which is to be explored while optimizing the die geometry. OptiXtrue then finds the optimum geometry with the minimum exit velocity variation within the design space defined by the specified ranges for the parameterized dimensions.

© 2020-2024 Plastic Flow, LLC. All Rights Reserved.