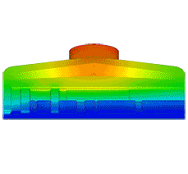

With the polyXtrue polymer extrusion simulation software...

You can specify material properties:

shear viscosity

elongational viscosity

thermal conductivity

heat capacity

density

wall slip

You can specify Processing Conditions:

flow rate

temperature

Now you will optimize:

geometry

processing conditions

material selection

* = Coextrusion Die Module only

To understand the capabilities of Plastic Flow products, please review the information on this page. For further details, please click on the links listed below.

polyXtrue Monoextrusion module

polyXtrue Coextrusion module

optiXtrue extrusion die optimization software

PELDOM elongational viscosity estimation software

eXtruemat software

Quickly and accurately determine:

velocity

pressure

temperature

shear rate

elongation rate

shear stress

elongation stress

streamlines (for each polymer)

residence time (for each polymer)

post-die extrudate shape

layer structure in final extrudate*

OptiXtrue automatically optimizes extrusion die geometry. It eliminates the need for virtual fine tuning of the die geometry by the user after each flow simulation in polyXtrue.

You will obtain:

An optimized die geometry for your extruded profile. The die geometry will be optimized for the minimum extrudate distortion.

You will provide:

Initial geometry of the die in SolidWorks or Inventor Software. You will parameterize, that is, designate as variables, some of the critical dimensions of the die which have the maximum effect on exit velocity distribution. You will also specify the range for each of the parameterized dimensions.

Elongational Viscosity Estimation Software

You will determine:

Axisymmetric elongational viscosity using entrance loss in capillary rheometer

Planar elongational viscosity using entrance loss in slit rheometer

You will capture:

Elongation thickening followed by elongation thinning behavior of the viscosity

Software for Estimation of Shear Viscosity Parameters

You will accurately fit:

Shear viscosity model to experimental viscosity data

Viscosity models allowed:

Carreau or Cross model for shear thinning behavior

Arrhenius or WLF model for temperature dependence

© 2020-2024 Plastic Flow, LLC. All Rights Reserved.

|

|---|